Overview

The equipment is widely used in the production of tomatoes, grapes, blueberries, mulberries, strawberries, kiwifruit, bayberry, raspberries, carrots and other fruits and vegetables crushing, separation and pulping.

The traditional fruit processing is to crush first and then take the pulp, and the pectin, pesticide residues, polyphenol oxidase, peroxidase, pectin methylesterase and other components in the peel, fruit stalk and fruit seeds enter the juice in large quantities, the result is that on the one hand, it increases the difficulty of subsequent separation and purification of the juice, and on the other hand, it also makes the comprehensive utilization of pomace troublesome.

The crushing cold beater can effectively separate the peel, stem and seed that are affected in the subsequent processing of juice pulp while crushing the material, so as to obtain high-quality juice or pulp, reduce the application cost of processing auxiliary materials, and improve the utilization efficiency of by-products such as peel, pulp, pomace and seeds.

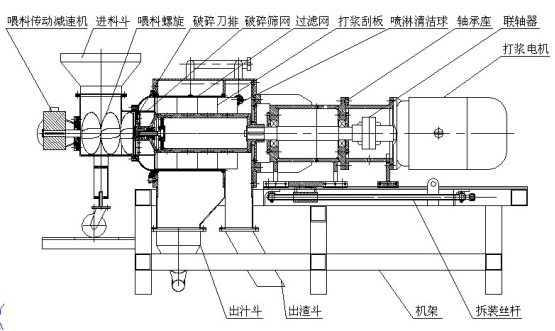

Schematic diagram of the main structure

Composition and working principle

The machine is mainly composed of important components such as frame, feeding transmission reducer, feeding hopper, feeding screw, crushing knife row, crushing screen, filter screen, beating scraper, beating motor, etc.

Its main working principle: the fruit and vegetable raw materials from the previous process enter the feeding spiral propulsion room, and the fruit and vegetable raw materials are pushed to the crushing mechanism by the spiral, and the crushed materials enter the separation and beating chamber, and the pulp and pomace are effectively separated under the action of high-speed rotating pulping scraper and screen.

The equipment integrates fruit crushing and pulping, completes the separation of pulp and undesirable components that affect product quality, and the content of polyphenols in the processed fruit is greatly reduced, thereby reducing the temperature required for passivating the enzyme, reducing energy consumption, reducing the probability of enzymatic browning, and improving the color value and stability of the product. Different materials choose different beating methods and different screen pore sizes, which can obtain the most ideal juice and pulping rate.

| Name | Technical indexes |

| Production capacity | 10t/h |

| Propelling power | 2.2kw |

| Crushing and pulping power | 45kw |

| Propelling rotation speed | 94r/min |

| Crushing and pulping rotation speed | 1480r/min |

| Outline dimensions | 3050 x 1280 x 1520mm |

Copyright © Jiangsu Kuwai Machinery Co., Ltd. All Rights Reserved | Privacy Policy | Blog